Gravel packing is a sand-control method used to prevent the production of formation sand. Gravel packing is used in conjunction with hydraulic fracturing, but at much lower pressures. Formation sand is produced from the breakdown of formations where wells are located. This occurs particularly in formations made of sandstone, limestone, and other similar types of rock. The main goal of gravel packing is to stabilize the formation and maintain well productivity.

During this operation, a steel screen is placed in the well – the well is then packed with gravel of a specific size to prevent the passage of formation sand. The operation requires slurry of properly sized gravel, water, and various chemicals, to be pumped between a slotted liner of the casing and the wellbore. The wire liner and gravel work together to prevent sand from entering the well stream.

Use as a well stimulation technique

Gravel packing as a well stimulation technique, also known as “frac packs,” was first used in the Gulf of Mexico in the early 1980s. The process involves simultaneous fracking and the placement of a gravel pack. The fracture is created using a high-viscosity fluid, to boost production rates, and prevent formation sand from being produced, while the associated screens stop the gravel from entering the produced fluids.

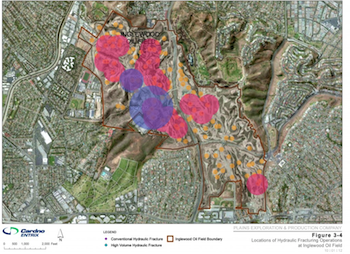

Frac packs have been used in Southern California’s Inglewood Oil Field since 2003. According to the Baldwin Hills Oil Watch, it has been used a total of 830 times since then, and was the first technique to exceed the fracture gradient in the surrounding formation. The fracture gradient is the pressure per unit of the depth of the well, usually measured in pounds per square inch (psi). When the pressure is greater than the surrounding rock, the rock cracks, and the fracture fluid moves further into the rock, extending the cracks further.

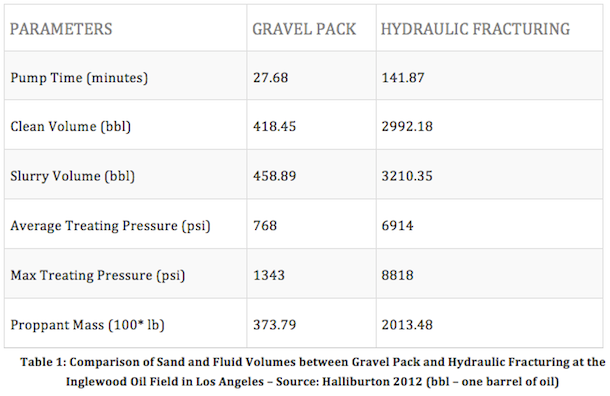

The materials for a gravel pack are pumped at much lower pressures than hydraulic fracturing, using less slurry, proppants, and other fracking chemicals. A gravel pack will influence a zone within 100 to 250 feet of the pack, while fracking affects an area up to 5000 feet. At the Inglewood Oil Field, estimates were that frac packs and other gravel packing operations would be used on as many as 90 percent of all new wells, due to the permeable sandstone geology of the area.

Gravel packing occurrences at the Inglewood Oil Field (shown in orange)

Source: Baldwin Hills Oil Watch

Regulation

Currently, there are no regulations on gravel packing in California. The practice would not be regulated under SB4, even though several groups, including Earthworks, have lobbied to have the technique regulated.

It is unknown if the practice is used in other formations throughout the US; however, it has been used in wells in Asia and the Middle East.